Over the years, manufacturers and milling contractors have jointly developed specialized milling methods for many different applications. The most commonly used techniques are introduced below.

Standard milling

|

Fine milling

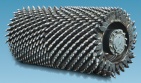

The adjacent photograph shows a fine milling drum with a milling width of 2 m and a tool spacing of 5 mm.

|

Slot cuttingSlot cutting is a special application to produce narrow cuts in asphalt pavements. The slots can be up to 10 cm deep at widths of 1.5 cm to 2.0 cm, and up to 30 cm deep at widths between 4 cm and 10 cm.

|

Milling tie-insWedged tie-ins are produced for butt connections or tie-ins to existing, intact pavement surfaces. Small milling machines are generally used for this purpose. This method allows solid compaction for the new pavement and produces a gentle transition from the existing pavement to the new, overlaid road section or a grade transition to existing fixtures respectively. Tie-ins produced with this method constitute a lasting repair and offer high riding quality.

|

Milling profilesA milling drum profiled on one or both sides is used for milling profiles. This method is particularly suitable for the removal of road markings or for the repair of cracks. These milling drums normally can mill to a depth of approximately 10 cm. |

Special fine milling drums with a tool spacing of maximum 8 mm are used

for fine milling. Depending upon the demands placed on the texture of the fine

milled pavement, the tool spacing may be even less (e.g. 5 mm). Fine milling

drums with working widths between 35 cm and 2.20 m are available in the market

for use in series machines.

Special fine milling drums with a tool spacing of maximum 8 mm are used

for fine milling. Depending upon the demands placed on the texture of the fine

milled pavement, the tool spacing may be even less (e.g. 5 mm). Fine milling

drums with working widths between 35 cm and 2.20 m are available in the market

for use in series machines.