Verband Europäischer Straßenfräsunternehmungen e.V.

Association of European Road Milling Enterprises

Glossar

Hier finden Sie ein Glossar in den Sprachen deutsch, englisch und niederländisch.

Milling tie-ins

Milling tie-ins

|

Milling small transitions adjoining the existing pavement. Tie-ins are usually milled using Small milling machines. This process creates the prerequisites for producing an at-grade transition.

|

Milling width

Milling width

|

Total width of the area to be milled, which may be significantly larger than the machine’s working width. |

Milling without loading

Milling without loading

|

When Milling without loading, the Milled material is left in the milling cut. Loosening the material may result in a reduction of the maximum Milling depth. Milling without loading increases wear and tear of the machine. |

Milling speed

Milling speed

|

Travel speed (advance rate) of the machine during the milling operation, usually indicated in m/min. |

Milled material

Milled material

|

Material granulated by the milling machine. It is not possible to define the Particle size and particle shape produced by the milling process. |

Milling performance

Milling performance

|

Milled area (area performance) or milled volume per unit of time, such as (m² / h) or (m³ / h) or (t / h). The Milling performance depends on Milling depth, material properties, site conditions, weather conditions etc. |

Milling depth

Milling depth

|

Difference in height between the upper edge of the existing pavement and the milled surface. Germany: see also ZTV BEA-StB 09 (Zusätzliche Technische Vertragsbedingungen und Richtlinien für die bauliche Erhaltung von Verkehrsflächen – Asphaltbauweisen = Additional technical conditions of contract and directives for the structural maintenance of traffic areas – Asphalt design). |

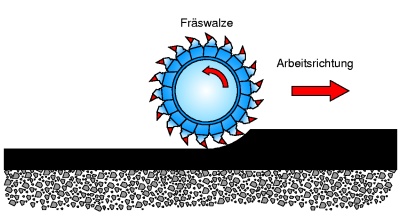

Milling drum

Milling drum

|

The Milling drum is the machine’s core component. It rotates against the direction of travel. Carriers (toolholders) are fitted on the Milling drum to accommodate the Cutting tools (point-attack Cutting tools).

|

Milling in layers

Milling in layers

|

Milling off the roadway in several layers. Roadways are frequently composed of several layers. To allow high-quality recycling, the pavements can be removed separately or in layers according to their layer structure (e.g. asphalt surfacing, asphalt binder course or asphalt base course). |

Machine width

Machine width

|

Width of the cold milling machine in operational condition. The Machine width is inevitably larger than the working width. |

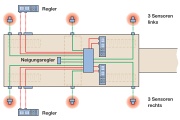

Multiplex levelling

Multiplex levelling

|

Additional Levelling system to minimize irregularities in the direction of travel of the cold milling machine (also called “Big Ski”). Several sensors scan the reference plane on one side or both sides of the machine. An optimized reference level results from calculating the mean value over a longer section of road. This enables any irregularities to be greatly reduced rather than being copied.

|

Milling grooves

Milling grooves

|

This is a special application performed by cold milling machines. It can be used to produce narrow butt joints in existing pavements.

|

Anschlussfräsen

Anschlussfräsen Aansluitingen frezen

Aansluitingen frezen